HT-HI castings are produced with an abrasion resistant iron with a minimum of 550 brinell hardness. The lifespan of our wear-resistant parts is more than twice as long as that of the ordinary ones. We strictly control the hardness, impact strength, elements, metal components and other parameters of our products, in order to ensure our customers only reduce high-quality vertical mill grinding balls.

To date, we have become the Chinese largest manufacturer of the wear-resistant parts for concrete and asphalt mixing plants. Each year we can produce 20,000 tons of wear-resistant Cr/Mn hard cast iron castings. Our highly-skilled engineer team can offer you complete technical support.

-

We offer the following castings

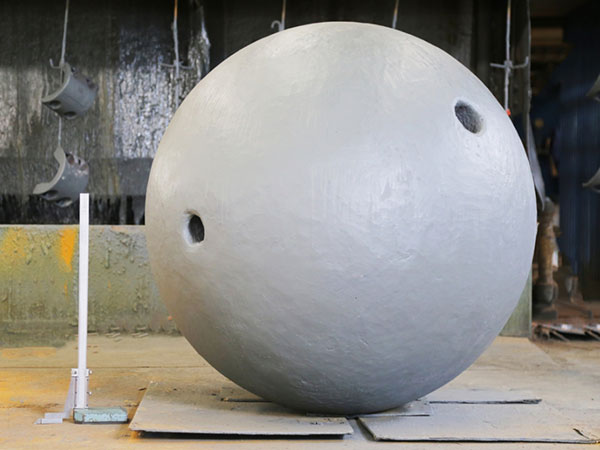

- Hollow ball for Vertical mill

Material Standards

Casting steel: DIN, JIS, EN, ASTM, GB

White chromium alloy castings: Cr content of 8%-29%.

Ni hard cast iron: containing 2%-6%

Manganese steels: with a Mn content of 13%-19%.

Low alloy martensitic steels

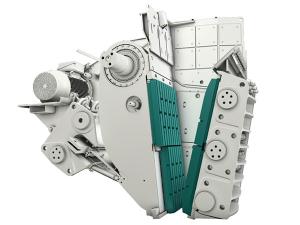

Brands Supported

Babcock & Wilcox, Metso, Sandvik, Nordberg, Symons, Hazemag, Keestrack, Powerscreen, Terex Pegson, Telsab, Telsmith, CITIC Heavy, SINOSTEEL

-

Our Advantages

- Precision mould making: 3D simulation PROCAST & Solidworks, accompanied with advanced casting technology ensures the moulds are exactly consistent with the drawings

- Advanced technology: HT-HI adopts DISA vertical automated moulding installations for green sand and chemical moulding, recycling of moulding sands of a mechanical and thermal type, smelting in MF electric induction furnaces, shot blast systems, natural gas heat treatment furnaces, deburring machines and machining equipment based on CNC technology

- Constant temperature control system from Dongzhi and patented filters for the casting line

- Direct-reading spectrometer from Thermo Fisher and BAIRD are employed for strict quality control

- How to Place an Order

- Please tell us the brand and model of your crusher.

- Give us the drawings or samples, and we will design and manufacture according to what clients have provided.

- The finished parts are sent to customers to confirm.